summary or the PRORAIL IPB

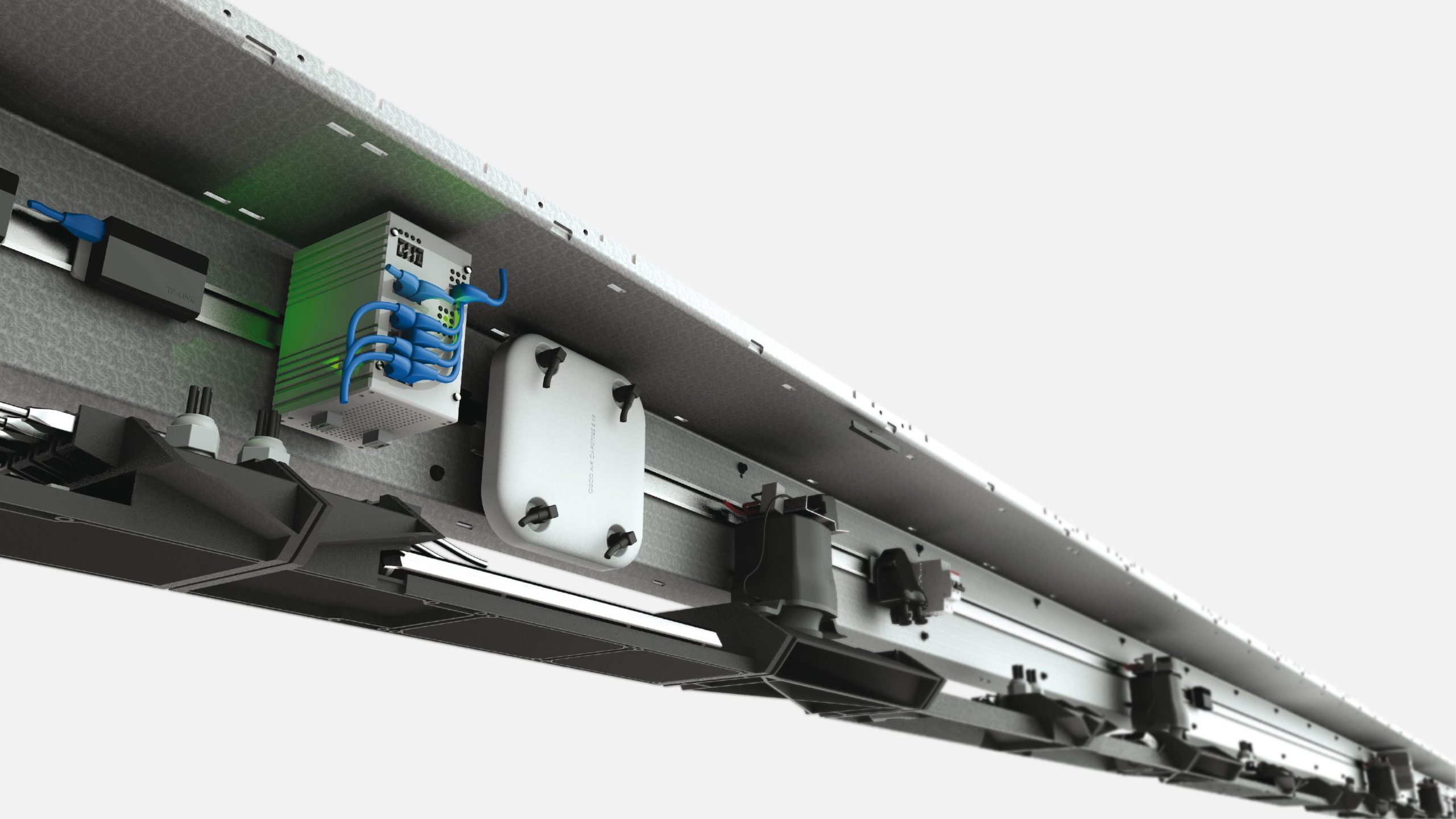

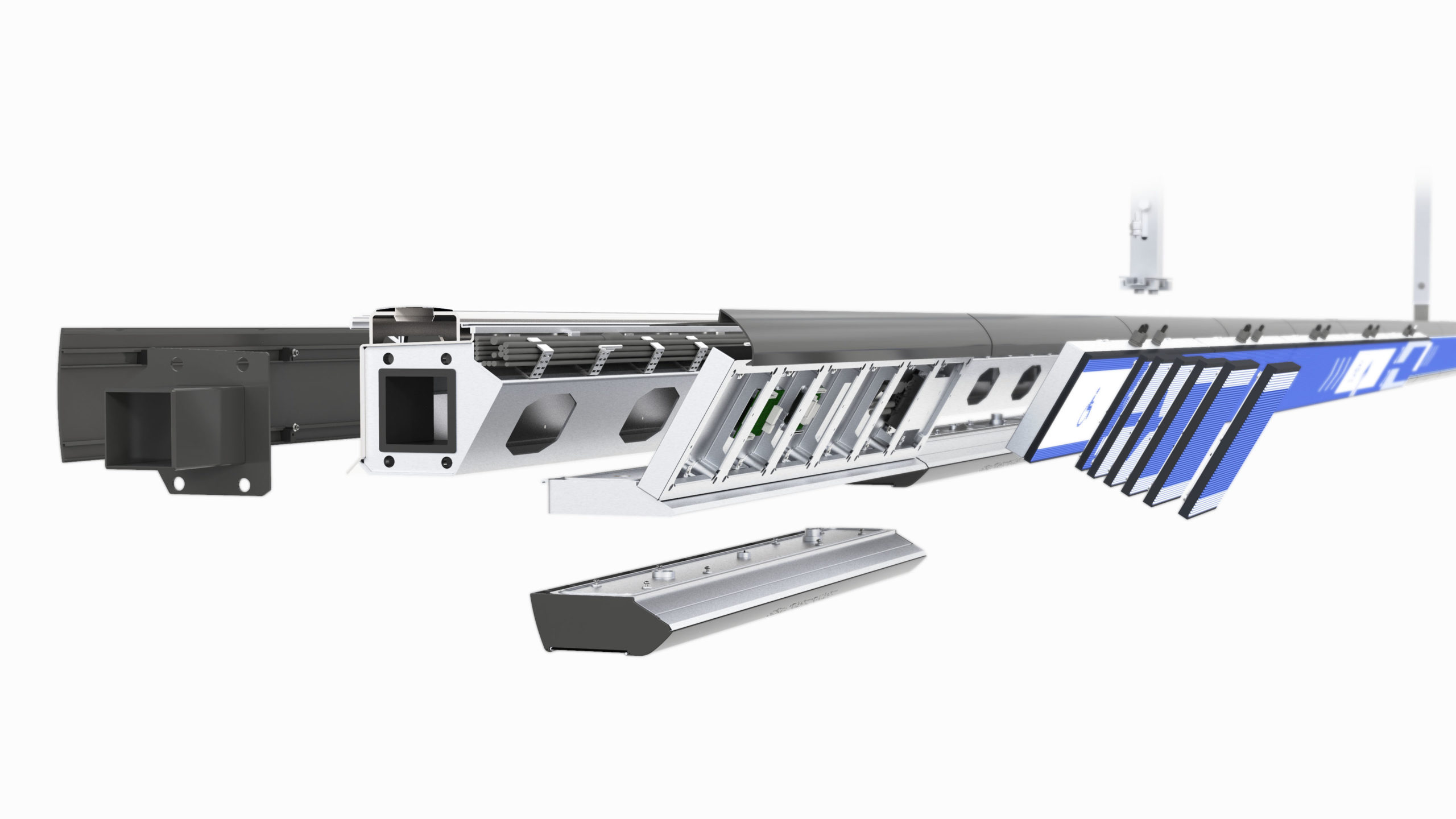

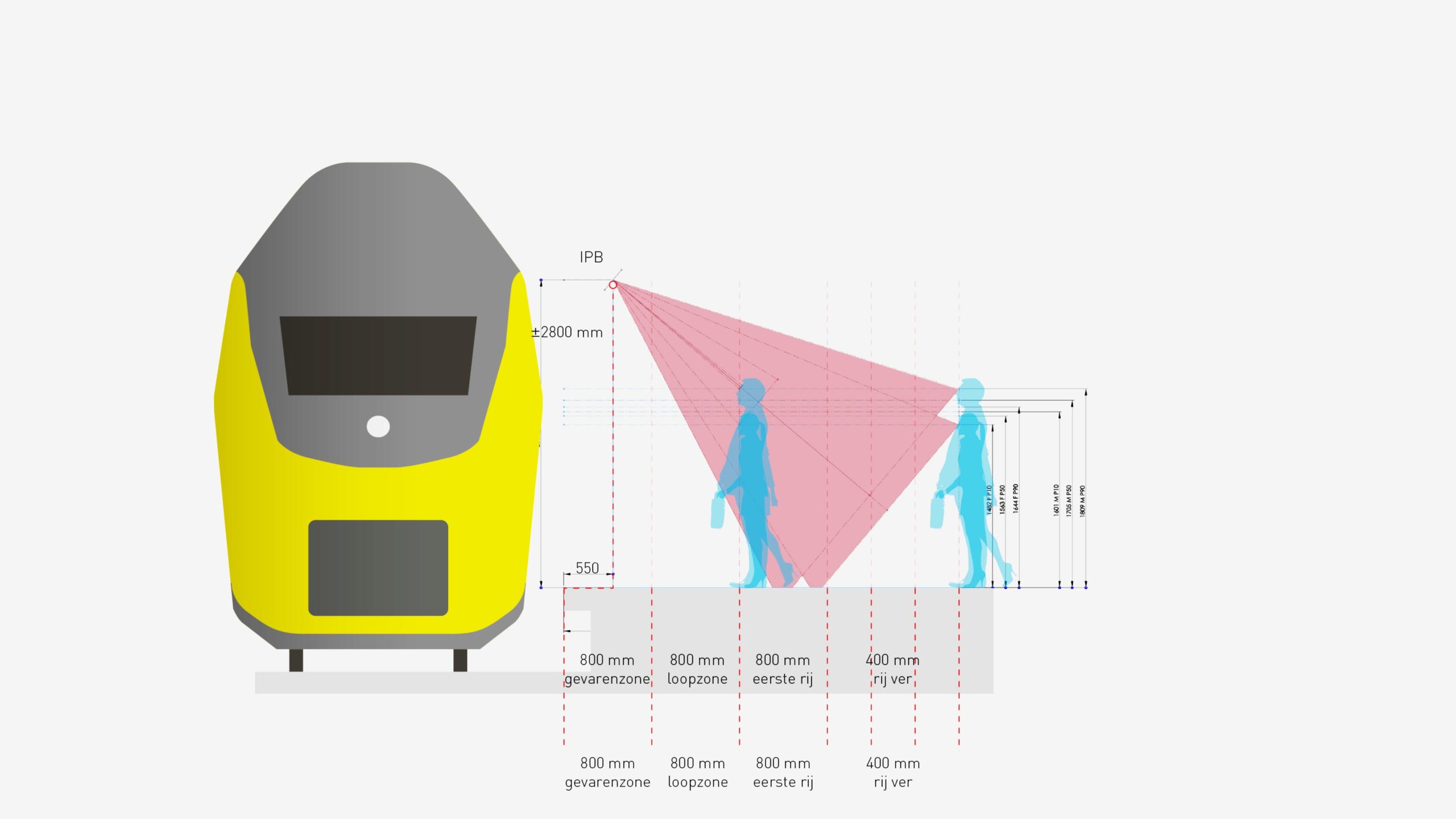

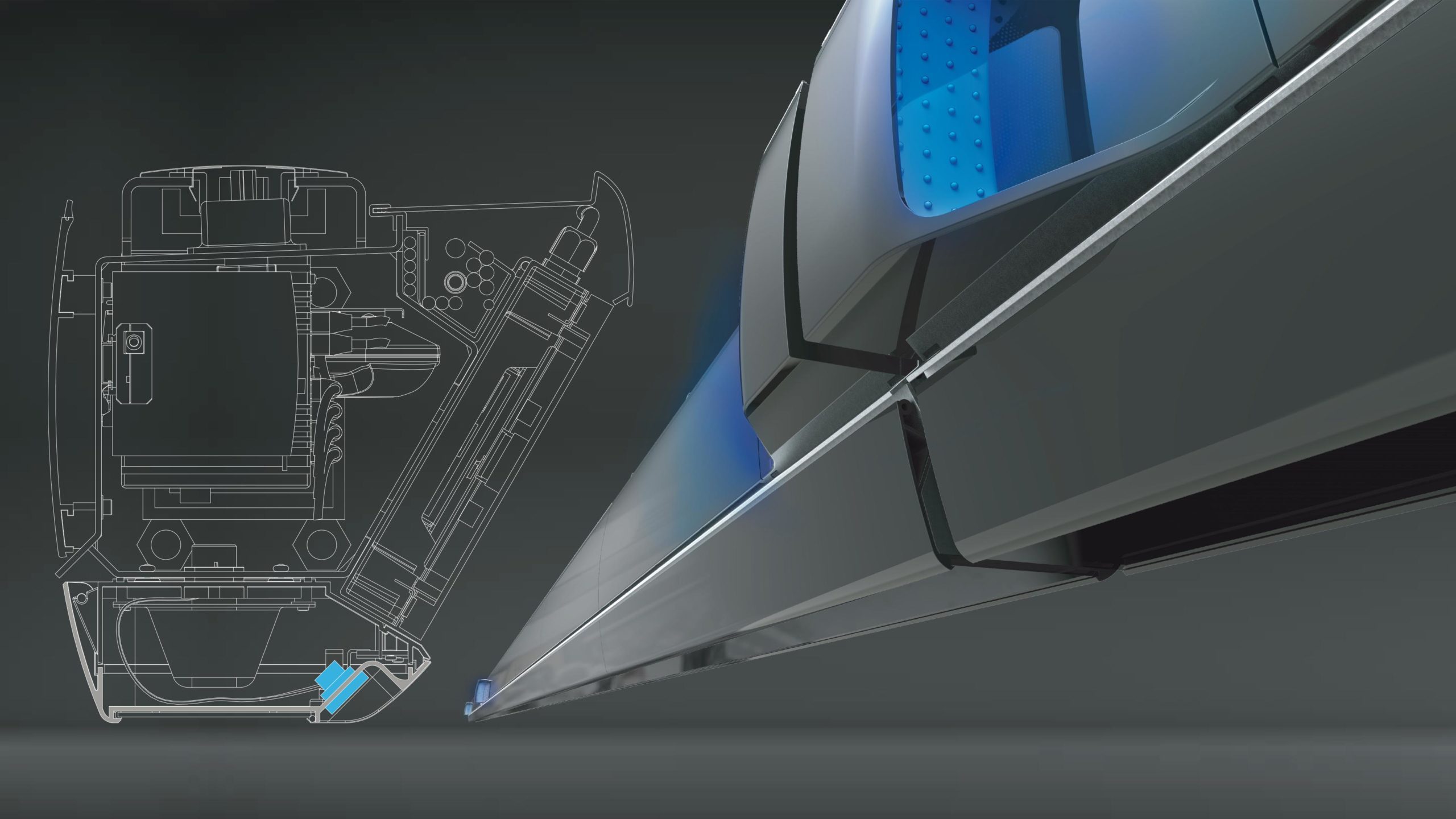

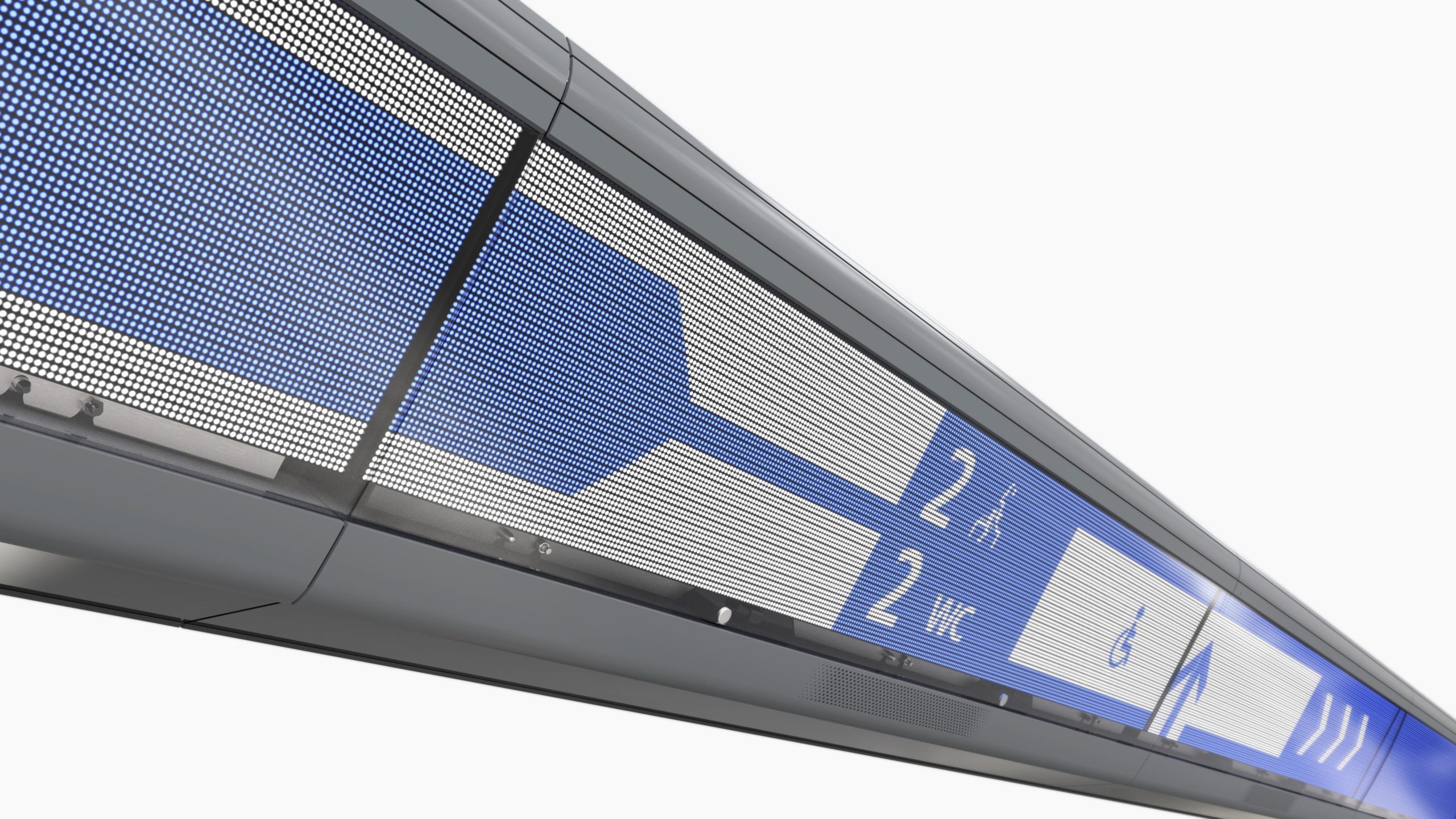

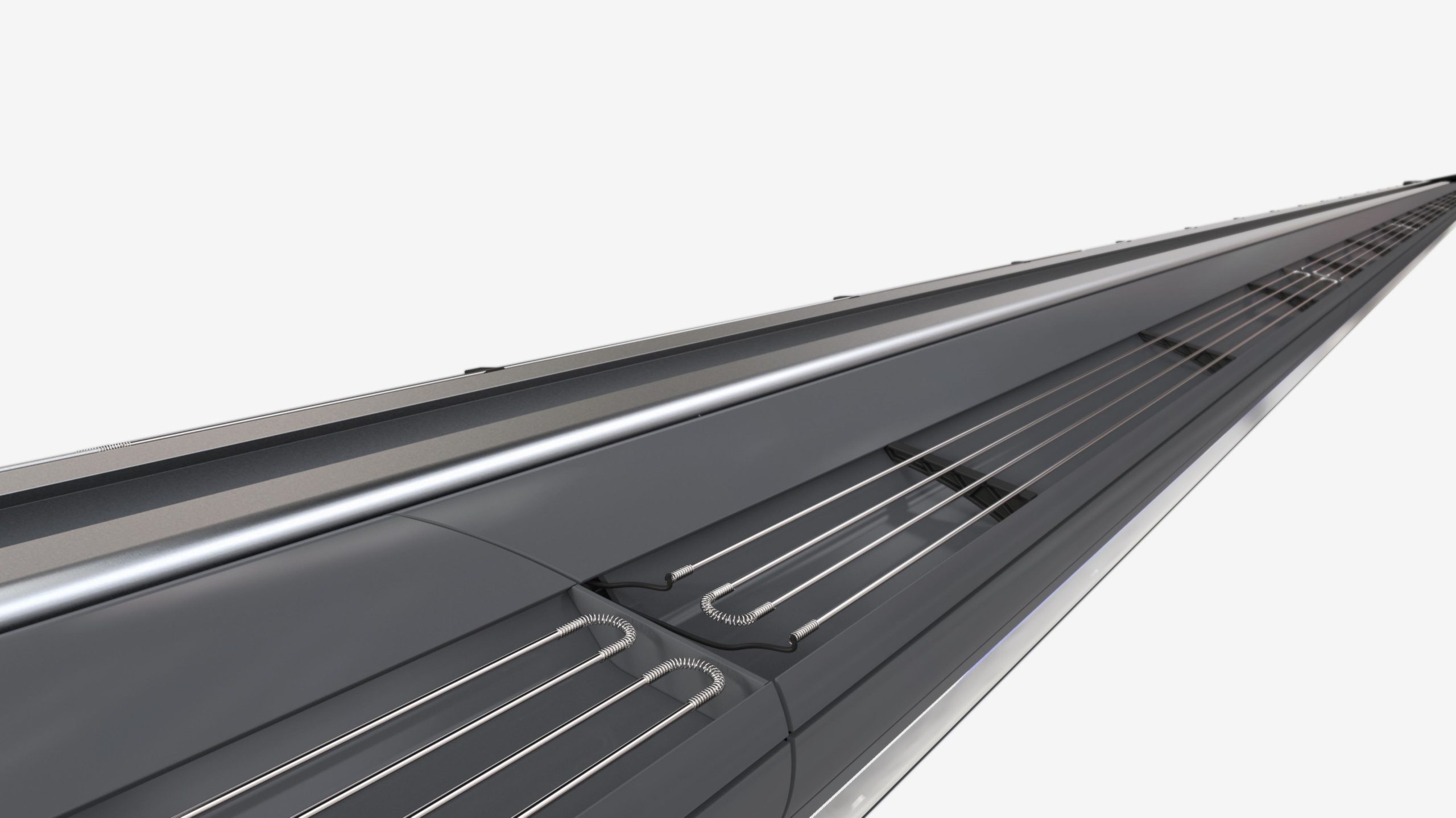

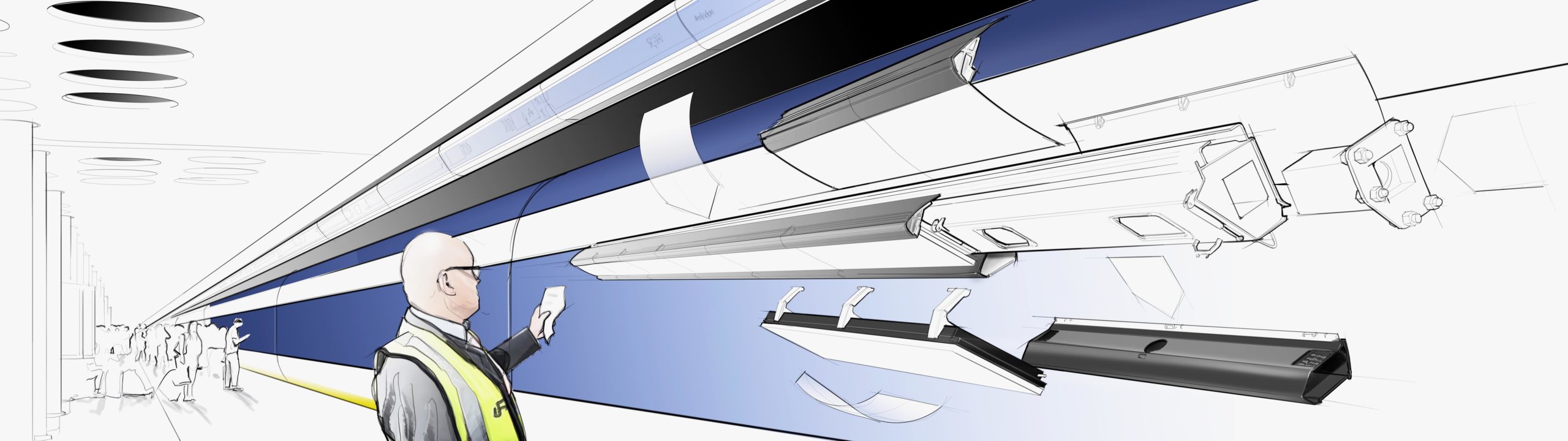

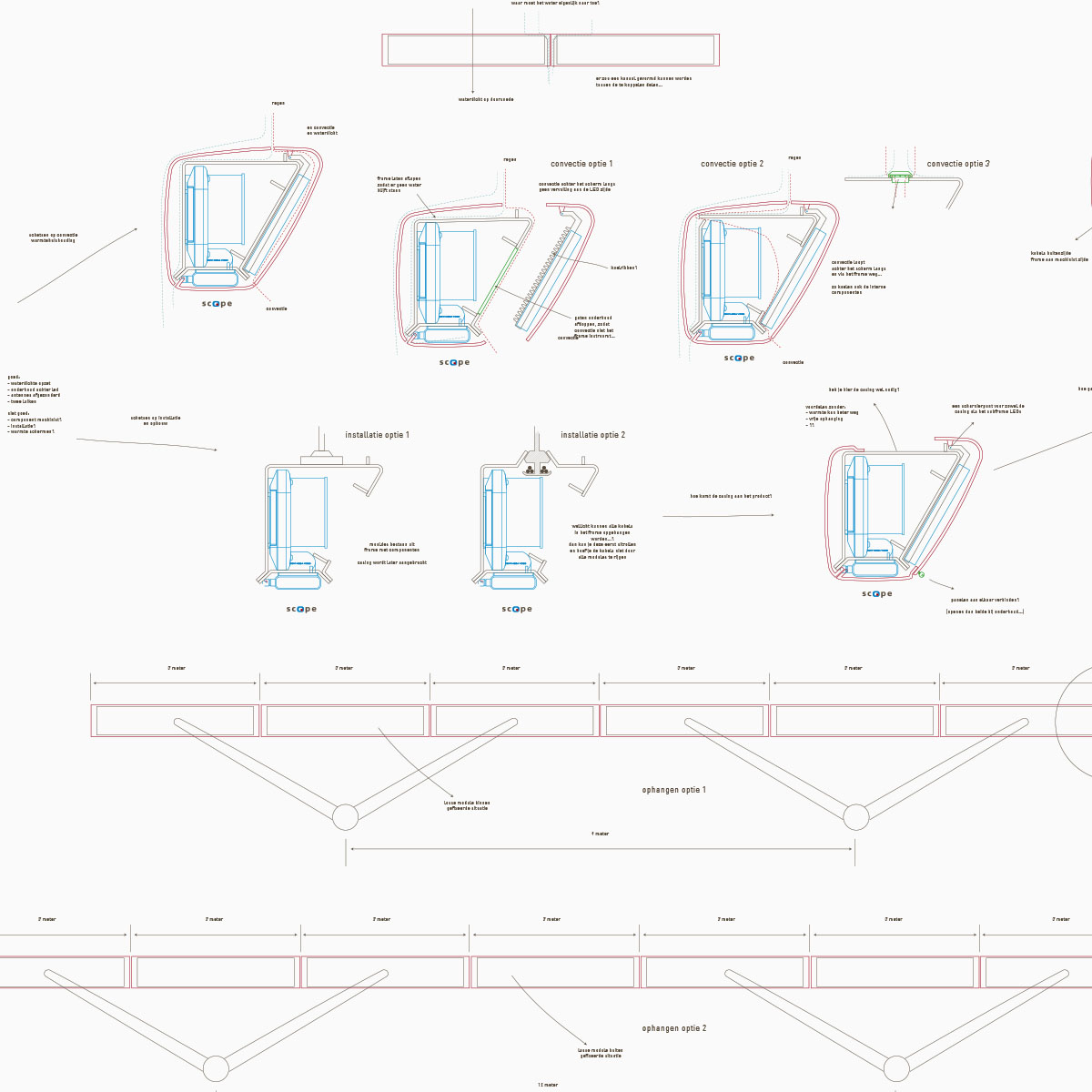

If passengers are better distributed on the platforms and know where they can board per train class, boarding and alighting will be faster and safer. ProRail was looking for an information system to better monitor and control passenger flows and which could withstand 'railway conditions'. Together with a team of experts from Atsence, KITT Engineering, Ngage Media, SIDstudio and Strict, Scope Design developed a maintenance-friendly, modular, intelligent information system that hangs freely above the platforms, so that both train traffic and passengers are not affected by it.