summary of Soilcares

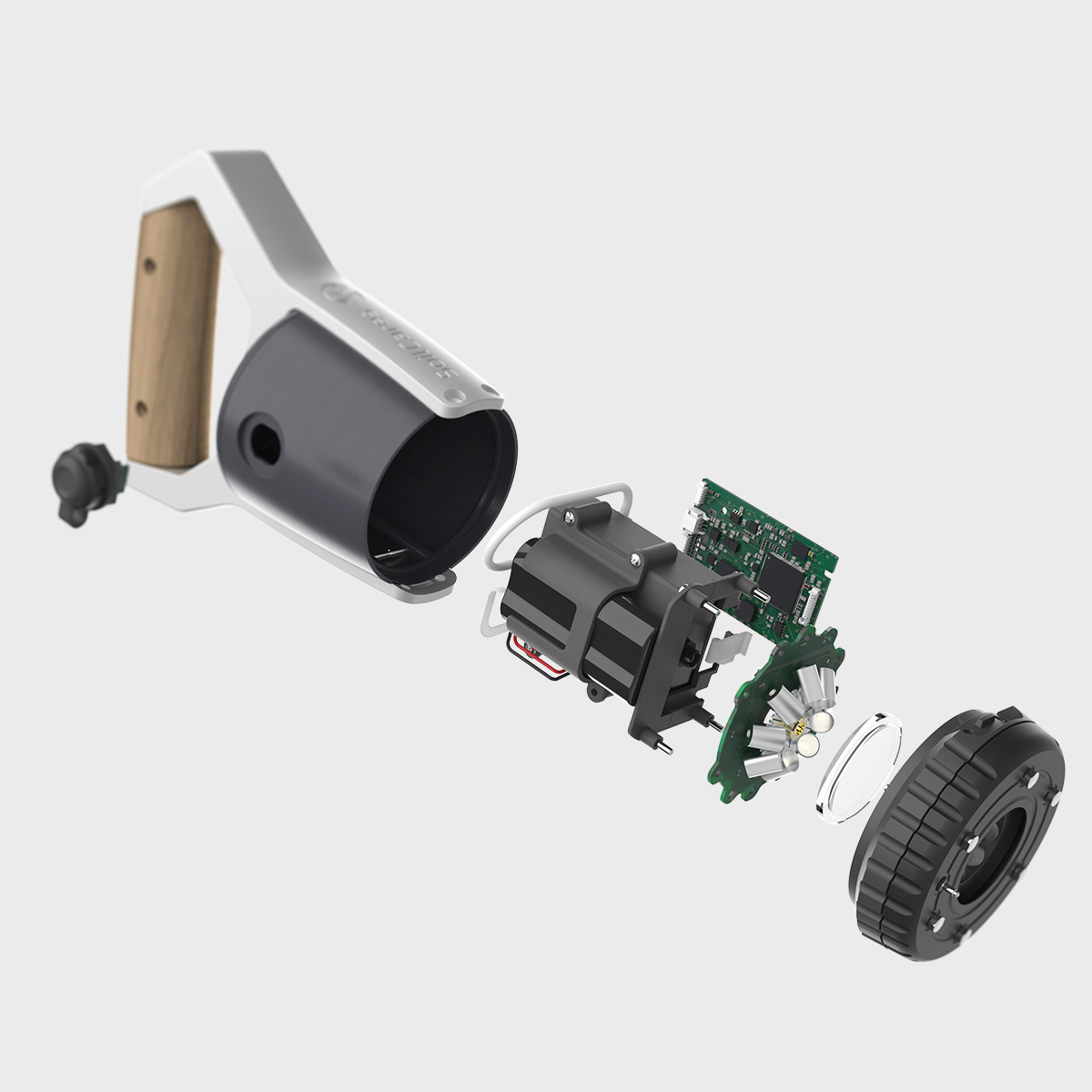

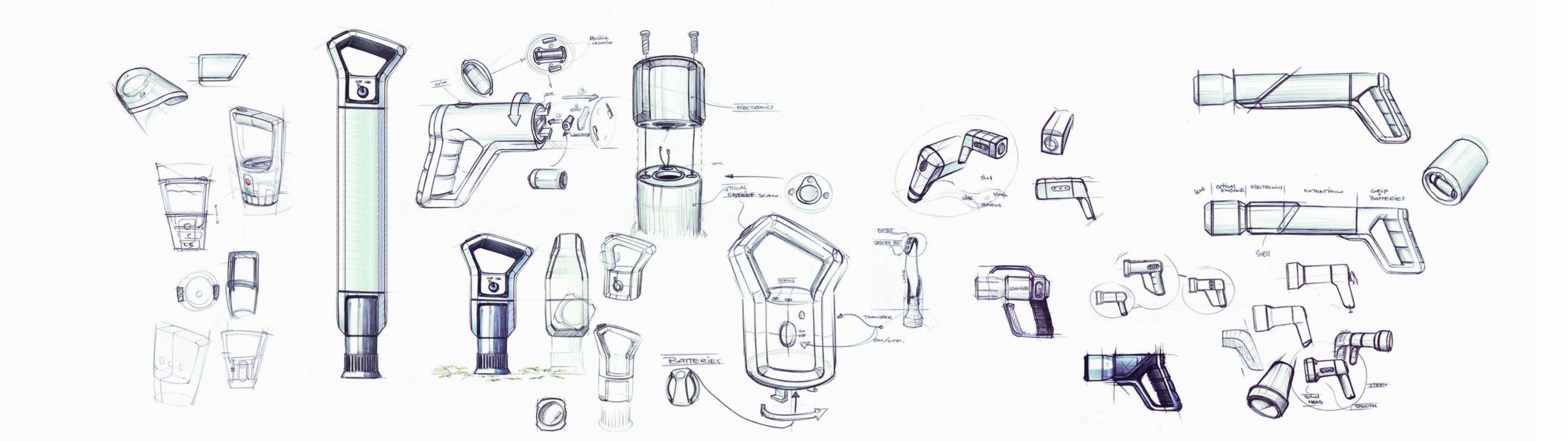

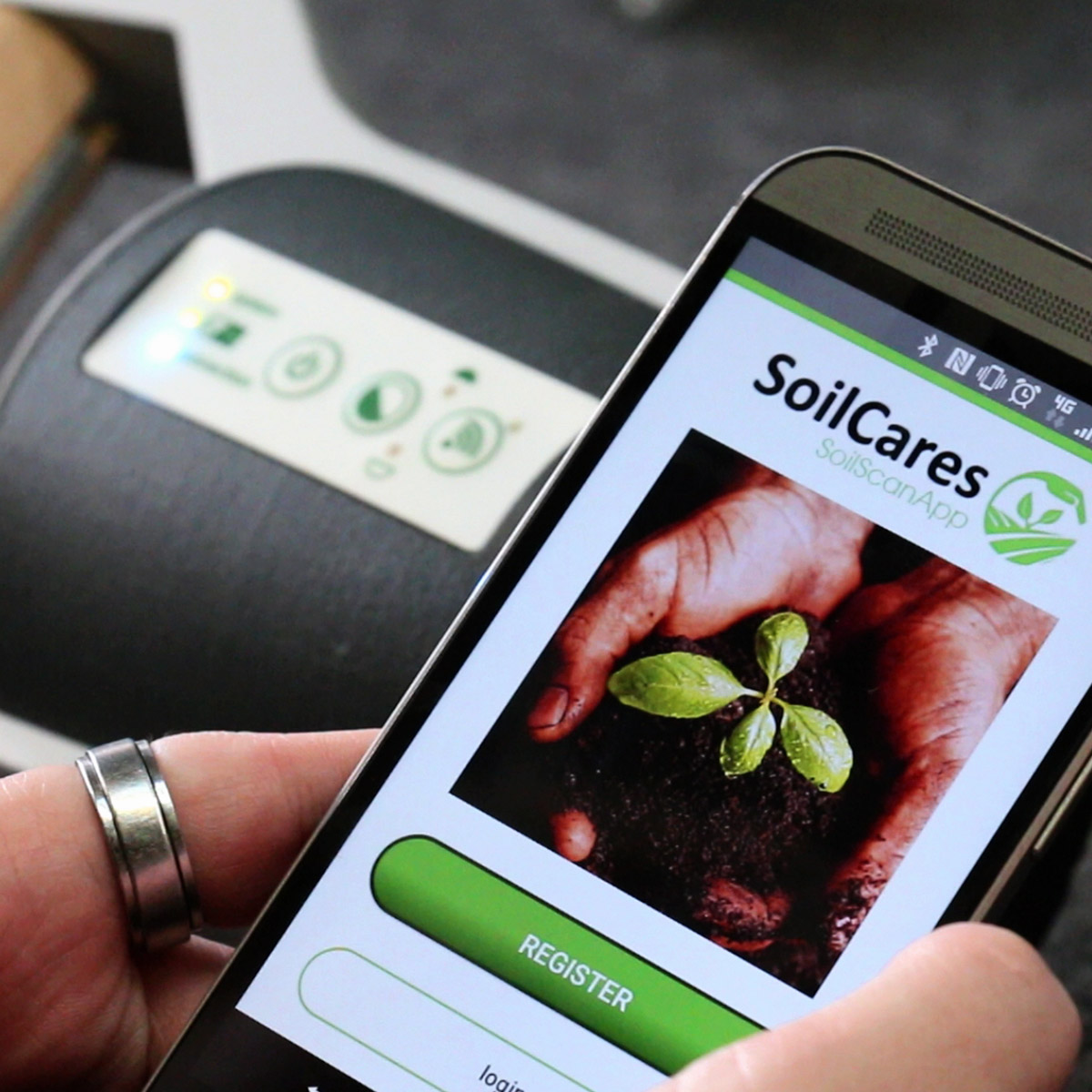

The Soilcares Foundation, affiliated with Wageningen University, asked Scope Design to take the lead in the development of a soil scanner. With this, farmers can quickly gain insight into the soil condition and then adjust the planting and fertilisation accordingly. Scope Design developed both the complex technology in the scanner and the robust, dust and watertight housing. It generated enthusiasm from the client and users and a Reddot Best of the Best for the technology and design.